The Inspection Report Makes Importers Fall in Love With Its Own Value

By For Safer Imports • 07/02/2021 • No Comments

In fact,inspection reports exist in every industry.As long as product inspection is involved,inspection agencies should be responsible for the inspection results,thus issuing an inspection report.However,the inspection report changes with inspection objects,inspection agencies, inspection effectiveness and other factors.For example,the inspection report issued by the manufacturer is a comprehensive inspection of various quality indicators of the product to assess whether the product quality meets the standards and meets the quality requirements of all designs.The inspection report issued by the quality supervision and inspection department is a kind of supervision and inspection work to charge for appropriate inspection fees from enterprises.The inspection report issued by the third-party inspection company is entrusted by the client to check whether the appearance and function of the product meet the requirements of the order.The inspector will sort out the problems and pictures into an inspection report.These also represent that the application of third-party inspection reports in different industries are different.

And the third-party inspection report really plays an indispensable role in international trade.As we all know,international trade is composed of manufacturers,traders,third-party inspection companies and importers,who can decide the validity of inspection reports according to their own position.For manufacturers,large manufacturers usually inspect each batch of products and send inspection reports to clients for checking,so that clients can be assured of product quality and achieve the purpose of purchase.However, if it is a small and medium-sized manufacturer,there will be no inspection report of finished products,but only the inspection report of raw materials.And it is also the laboratory test commissioned by the raw material manufacturer. Therefore,if importers cooperate with small and medium-sized manufacturers,they usually arrange for a reliable third-party inspection company to inspect the goods.They check the third-party inspection report to confirm the average quality of the goods.

In the eyes of traders,the inspection report is also a proof to show clients the quality of products.But the difference is that the inspection process of traders is quite different from that of third-party inspection companies.Because the goods are delivered to their own factories for production,or transport it to the factory they are cooperating,traders know the products best.In this case,they will think that every process of product production has been strictly checked.If the client arranges the inspection,they only need to take a picture and measure the basic parameters,which will be showed in the inspection report.Therefore, CQI also learned from some importers that they did not trust the inspection process of traders.And would ask them to find a third-party inspection to inspect. For the third-party inspection company,the inspection report reflects the average quality level of a certain batch of goods to the client.The client can confirm the production situation of the goods through different parts of the report and decide whether to ship or not.Because the position of the third party inspection is different from that of manufacturers and traders.And the responsibilities are different,the inspection report issued by the third party is professional and effective.Most importers will require factories to improve production technology and product quality according to the third-party inspection report.It can be seen that the inspection report can directly reflect the inspection workload to the client.And the client can also judge the authenticity of the inspection work through the inspection reports issued by different third parties,so as to choose the inspection company with high cost performance.

Third-party inspection reports understood by different business objects

Factory

Generally,the inspection reports that factories can get are divided into two types: inspection reports for raw materials and inspection reports for finished products. The former is the qualification certificate required by the manufacturer when the factory buys raw materials.And the factory will back it up in the database in case the client needs it. Therefore,compared with the inspection report of the finished product,the factory pays more attention to the inspection report of the raw materials. After all,it can prove that the raw materials used in the product meet the requirements.Moreover, the factory will indicate to the client that it has strictly controlled the production of the product.They believe that the inspection of the finished product is unnecessary.The inspection report is even more superfluous.

Trading company

As mentioned above,the inspection process of trading companies is relatively simple,so the inspection report is only a few pages. Because in their view,the inspection report is just a piece of paper and it is a formalism,which has no substantive significance.However,if it is required by clients,they will try their best to satisfy them,even though they look down on the inspection report.

Importer

Since importers choose to import goods in China for a long time,what they worry about most is the quality of the goods.Among them,the most effective solution is a comprehensive third-party inspection report.They usually urge the inspection company to send the inspection report to them before shipment, because they need to judge whether the quality of the goods meets the requirements through the inspection report.It can be seen that the importer’s payment of inspection fees is directly proportional to the return and even more than that.

Ultimate buyer

The ultimate buyer can be understood as the ultimate distributor.For them, before receiving the goods, the goods may go through a lot.And it is impossible to guarantee what the goods will be when finally delivery to buyers.However,buys can compare the goods with the third-party inspection report. They check whether the defects or functional problems mentioned in the inspection report still exist,so as to decide the destination of the goods.In the eyes of the ultimate buyer,the inspection report is a comparison proof.

Third-party Inspection Company

As long as it is an inspection company,it is necessary to issue an inspection report after the inspector completes the inspection order.However,due to the different views on the inspection report,the effect of the inspection report can not meet the importer’s expectations.It depends on the business philosophy of an inspection company.And whether they conducts the inspection fairly.The inspection report of inspection companies that can do this is usually a good proof.

According to the different business objects,the views on the third-party inspection report are also very different.In any case,the inspection report is always used to reflect the quality of goods,but how to reflect it concretely?

What Does a Comprehensive Third-party Inspection report Include?

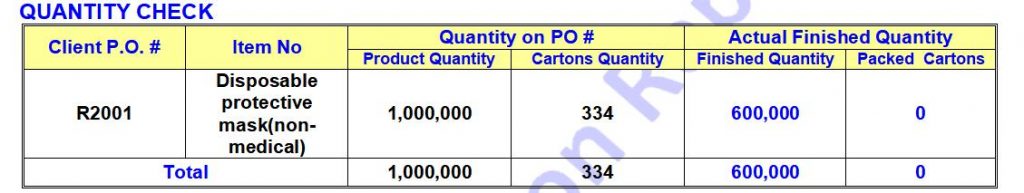

Quantity Table

Before inspection,we will receive the product list sent by clients or traders,including product quantity,product specifications,carton specifications and text information.Such a product list can help inspectors verify the production situation of products and obtain the completion ratio of goods by counting on site.A clear quantity table can reflect the completion of each product to clients.Once the completion rate of a certain product is very low,the client may ask for re-inspection to ensure that a certain quantity of each product can be sampled.

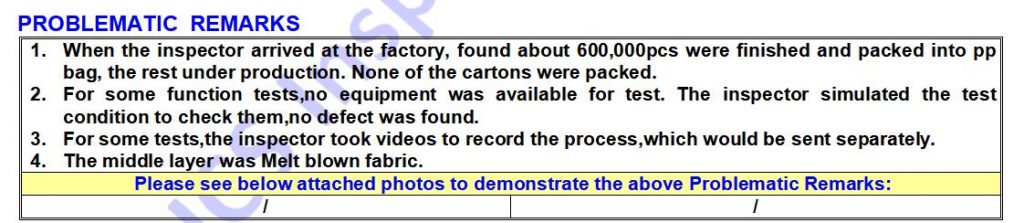

Important Remarks

Important remarks,which are used for clients to conveniently read and understand the most important contents of this inspection result.In the remarks the inspector will describe the production situation, batch problems,testing situation and potential risks of the products.And attach relevant pictures.Clients can quickly grasp the inspection situation on the front pages of the report.If there are many problems that need to be noted,CQI inspection will highlight important remarks to avoid clients’ omission and cause irreparable consequences.

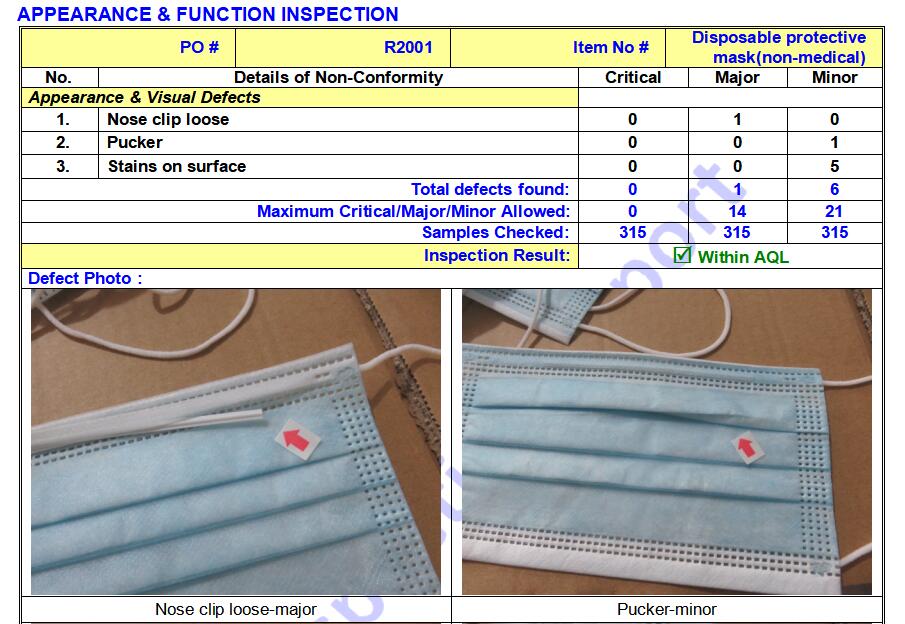

Product Defect Records and Statistics

At the inspection site,the inspector will classify the defects found.Ensure that when editing the inspection report,the sorted defects can be fully showed in the report.According to international practice,the number of sampling is to comply with the prescribed sampling rules.In this way,we can get an acceptable defect value,once the total number of defects actually found exceeds the acceptable range.It shows that the quality of this goods is fail.

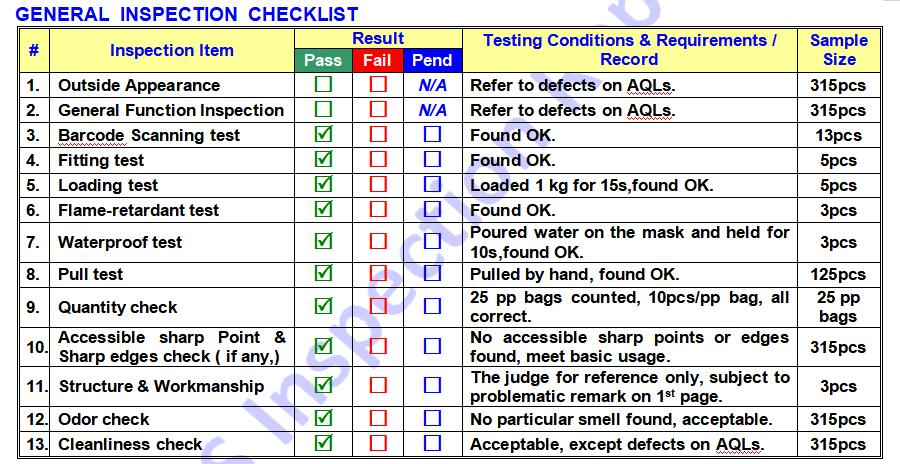

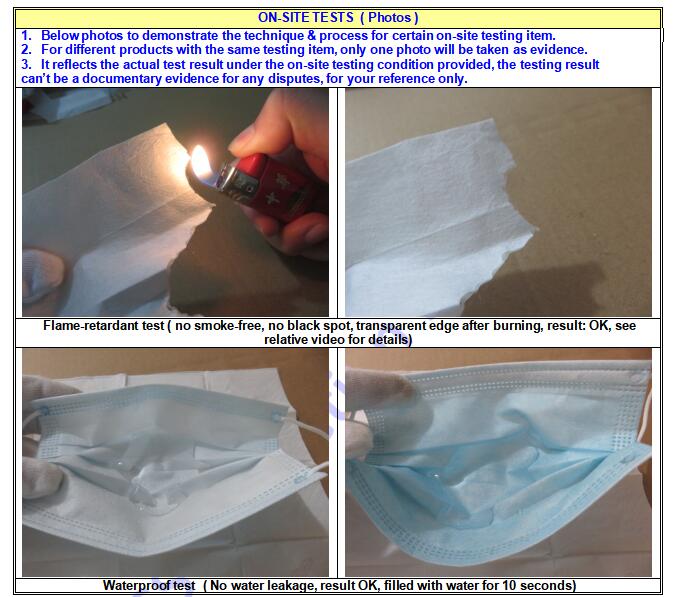

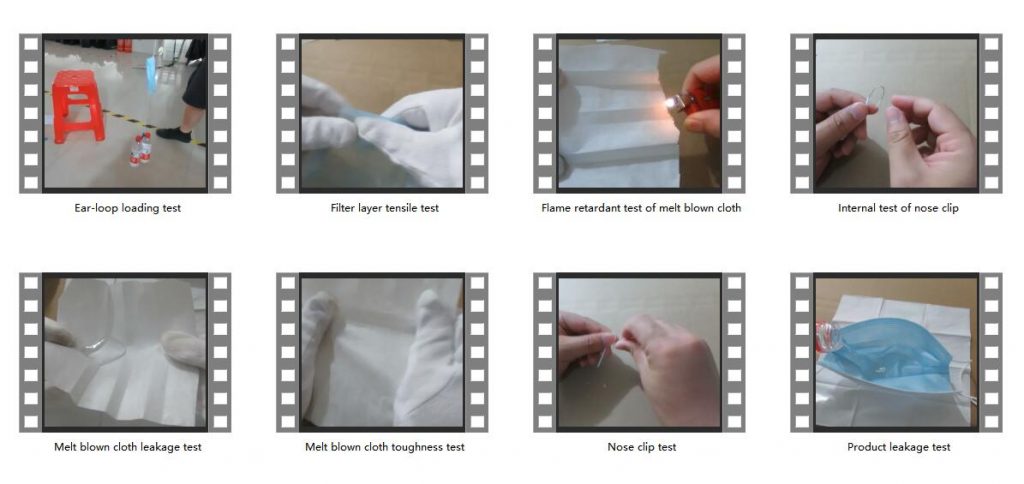

On-site Test Items for Product-related Intrinsic Quality

Each product has a test specified by CQI.And the inspector showed the result of each test in the test table.Clients can not only see the workload of the inspection through the test table, but also the inspection quantity of each test.From the test, the client can witness the actual use function of the product and verify whether each function is consistent with the production order.So as to ensure the production schedule of subsequent orders.

Necessary Videos of Product Test

CQI inspection adds a small video to the test.In order to be able to more intuitively show the test results.Because many tests simply pass the pictures and cannot show the test results well.A 15-25 seconds video allows clients to see the operation of product functions more clearly.At the same time, the video processing is relatively simple and the speed of transmission to the client is faster.For the ultimate buyer,it will be more at ease to see the products they purchased through the video for the first time.

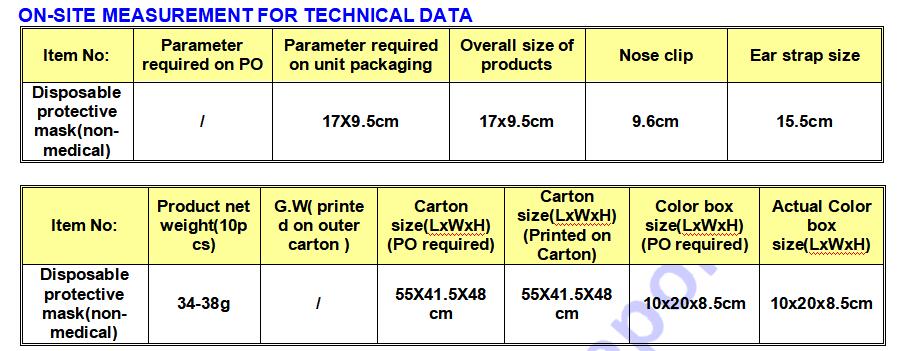

Form for Recording Key Data of Products

The average value calculated from multiple sets of data is used to measure the product specifications,so as to ensure that the product design meets the order requirements.It is worth noting that clients can know whether the factory has cut corners by weight.And only need to compare the actual weight with the confirmed sample weight.

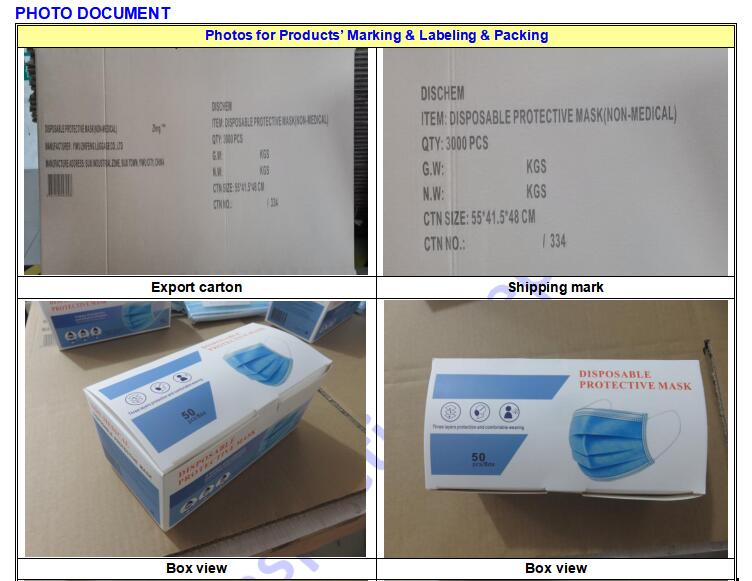

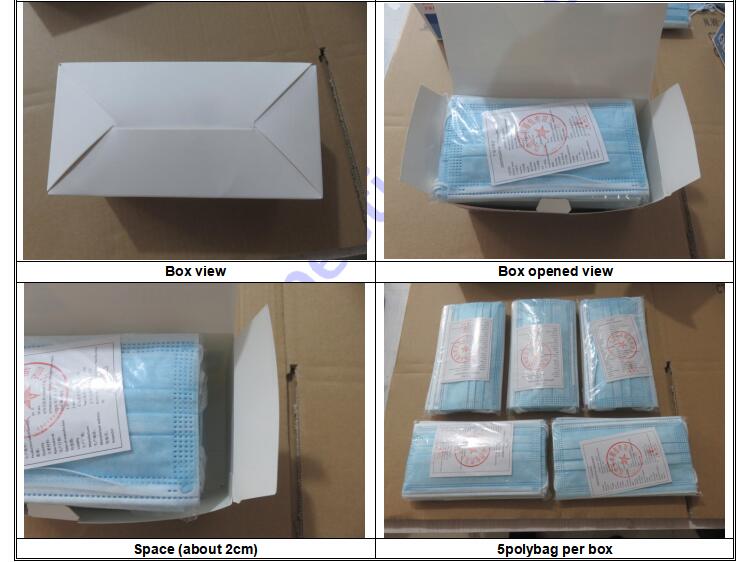

Product Information Picture

A comprehensive record of all aspects of the product,clients can intuitively understand all aspects of the product.This part is mainly composed of photos,from shipping mark,bar code,carton open view, color box appearance to product details.The inspector shall check the actual information and check whether it is consistent with the order data,especially the product design.From the complete photos,the client can see the bulk production of each product and decide whether to arrange the shipment.

The above six parts are the main components of a comprehensive inspection report.They all play different roles but they are indispensable.In particular,CLI inspection adds test video which not only makes photos and texts vivid,but also shows the testing process vividly in front of importers.How can importers refuse to use such a third-party inspection report?

Why Do We Recommend That Client Adopt the Inspection Report Template of CLI?

The inspection report of CQI is a comprehensive document that feeds back the actual inspection situation. Usually, the number of pages of a report is about 50 to 100 pages.Through every part of the report,from product quantity to product detail drawing,clients can intuitively understand the production situation of bulk production.That’s why we recommend that clients use the CQI inspection report template instead of a report with ten or twenty pages.Most of the time,the format of the client’s own report is also very simple,because they think that the inspection report is just a form,so there is no need to be so complicated.Obviously,the idea of such clients is completely wrong,unless they buy high-end products and there is no need to worry about the quality.

We hope that clients can understand and experience the value of the third-party inspection report.And then they will understand that we do not give empty talk.In fact, clients can easily compare the difference between valuable inspection reports and worthless inspection reports.Once the goods are defective,they can realize the value of inspection reports more directly.

A Case Clearly Shows and Analyzes the Value of the Inspection Report

Above,we emphasized the value of the third-party inspection report,so what value can the inspection report have in actual inspection? In an inspection of ladies’ sandals,the inspector found that the products not only had serious defects,but also had many batch problems.Because this is a PU leather high-heeled shoe,the leather damage,missing glue on heal and wrapped toe found by the inspector, which are major defects in the product.There is also the batch problem of thread end and color deviation. And this inspection report will fail.

From the communication between the inspector and the factory,we know that this is the first time that the factory has cooperated with clients.And it is the first batch of orders since the establishment of the factory. One of the products is outsourced to another small factory and workers are only responsible for assembly.The factory took the production right of this products through traders,but didn’t take seriously of the product quality.After the client received our inspection report,he verified the records in the report with us.Then he told the factory immediately that all the goods must be reworked and re-inspected.Although the second inspection barely passed,we found that this high-heeled shoe was produced in another factory for the third inspection.Obviously,clients have eliminated the first factory from their supply chain system.And tell the problems found in the first inspection to the new factory,so as to avoid the same situation and reduce losses in advance.

It can be seen that a valuable inspection report can tell the client what scale the factory he cooperates with and what the quality management level the factory has. It helps clients select high-quality factories and prevent the risk of complaints.

Are There Any Differences in the Inspection Reports of Different Inspection Service Items?

Because pre-shipment inspection is the most frequently used inspection service by importers,only its inspection report is the most valuable,which is a wrong view.Although there are some differences in the contents of the inspection reports for each inspection service,their functions are the same,with the aim of reducing the risk of importers importing goods from China.Next,we will specifically look at the differences:

Since the initial production inspection is carried out under the production requirements with 10%-20% of the goods,the inspection report mainly includes the audit of raw materials,the status of products on the production line and the production of accessories.Once there is a problem in a process,the inspector will show the problem in the remarks for the client to check in time and stop loss as soon as possible.

At during production inspection,30%-50% of the products have been produced. Therefore, the inspection report can not only show the quality of finished products,but also show the production of semi-finished products on the production line.By checking the mid-term production progress of products,it is a wise inspection method to avoid batch problems in the remaining unfinished products.And it also lays a foundation for the following pre-shipment inspection.

When the client agrees with the management of factory he cooperates with,he usually arranges pre-shipment inspection. At this time,the goods have completed 100% production.The inspector can feed back the overall average quality level of the goods in the inspection report on the premise of maximizing the sampling range. Clients can check the quality of the whole batch of goods through the inspection report,so as to decide whether to arrange shipment or not.

In this inspection report,the client can see whether the actual shipment quantity of goods is consistent with the contract and there is no shortage.Through the pictures,the packing method of goods in transit is well showed in the report. After the goods arrive at the destination port, unloading the goods and counting them is a job that needs much energy from warehouse keeper and also requires them to be careful,so the report of container loading inspection can help them count the number of cartons more conveniently.

The purpose of factory audit is to audit all aspects of the factory before the first cooperation. Such as factory equipment,factory workshop,factory hygiene and related certificates.These conditions will be showed in the report through pictures.And if it is necessary, the inspector will also take videos to show the capacity of the factory.According to this inspection report,the client can judge whether the factory meets the management and production requirements to decide the cooperation of each other.

What is the Draft Report?

The “inspection report” seems to be simple words,but each word takes big responsibility.From different business objects’ understanding of the third-party inspection report to the composition of the inspection report and then to the existence value of the inspection report.Each paragraph fully explains its significance to importers. However,many importers may think it is unfounded,but we can prove it through practical cooperation.After all, practice is the sole criterion for testing truth.

Moreover, we can see that different business objects have different understandings of the inspection report.Once a certain aspect is misunderstood,it may lead to an increase in the risk of product complaints and cause irreparable losses.However,from the composition and value of the inspection report,it is an inevitable result to reduce the risk of complaints,which is also the pursuit of CQI inspection With such obvious selection results,CQI believes that importers will make wise decisions.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.

For Safer Imports

Search

Catalogue

Recent Post

- CQI Inspection Report

- Folding Table: Technological Comparison Between Two Factories

- Tear off the Label Made in China of “Good Quality and Low Price”, Don’t Spoil the International Market

- Do You Know Those Important Material Tests for Car Floor Mats ?

- In 3 Months, Furniture Maker Improves Quality So Much, But Why…

2543 2607 2659 2667 2676 2682 2683 2685 2687 2692 2693 2699 2700 2705 2708 2714 2715 2716 2743 2744 2746 2748 backpack defect check Children furniture quality control China disposable medical gloves Electric toothbrush cost Electric toothbrush inspection Electric toothbrush waterproof inspection Electronic scale quality inspection Glove testing consultation infrared thermometer testing consultation Lighter inspection Lighter process inspection Mask inspection nitrile gloves inspection Pajamas process inspection Plastic clip quality check Quartz watch inspection Quartz watch process inspection Sofa bed inspection solid flooring inspection stainless steel quality control Umbrella process inspection Wenzhou shoes inspection Zhangzhou watch inspection

BLOG

- CQI Inspection Report

- Folding Table: Technological Comparison Between Two Factories

- Tear off the Label Made in China of “Good Quality and Low Price”, Don’t Spoil the International Market

- Do You Know Those Important Material Tests for Car Floor Mats ?

- In 3 Months, Furniture Maker Improves Quality So Much, But Why…