By For Safer Imports • 07/19/2021 • No Comments

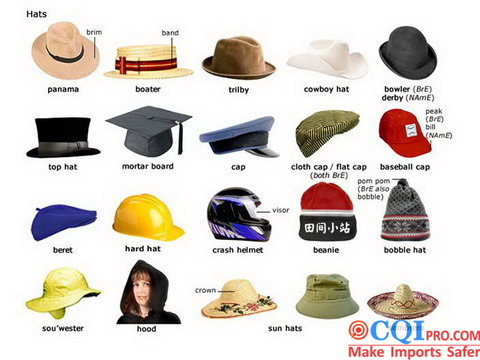

A hat, an ornament worn on the head, covers most of the entire top of the head. The hat is mainly used to protect the head, and some hats have protruding edges that can block the sunshine. Hats have the functions of sunshade, decoration, warming and protection, so there are many different kinds of products, and there are many different requirements for product selection. In the hat inspection process, different types of hats have similar test methods, but the size and style are not allowed to be wrong.

According to the detailed method, the hat can be divided into: hat top, cap roll brim, hat wall, hat brim, hat lining and hat ribbon. Simple can be divided into: hats top, hats brim and decorations.

Complete process: raw material preparation – cutting – sewing – printing or embroidery – sweat band – ironing setting – packaging

Among the important aspects are:

Appearance class:

Function class:

Inspector field test in the hat inspection

Because hats belong to a category of clothing, the quality requirements for sewing are the same as clothing, and even more stringent. Through the hat inspection, strengthen the production control of the factory and improve the right product quality control allows importers to see the quality of their products and improve their product design, enabling importers to break into competitors and make profits.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.

2543 2607 2659 2667 2676 2682 2683 2685 2687 2692 2693 2699 2700 2705 2708 2714 2715 2716 2743 2744 2746 2748 backpack defect check Children furniture quality control China disposable medical gloves Electric toothbrush cost Electric toothbrush inspection Electric toothbrush waterproof inspection Electronic scale quality inspection Glove testing consultation infrared thermometer testing consultation Lighter inspection Lighter process inspection Mask inspection nitrile gloves inspection Pajamas process inspection Plastic clip quality check Quartz watch inspection Quartz watch process inspection Sofa bed inspection solid flooring inspection stainless steel quality control Umbrella process inspection Wenzhou shoes inspection Zhangzhou watch inspection