Do You Really Know About First Article Inspection?

By For Safer Imports • 07/02/2021 • No Comments

First article inspection can effectively help international importers to ensure that the manufacturing factories of exporting countries fully understand and manufacture large quantities of products according to the requirements of importers before mass production in the initial stage of transnational procurement.During the first article inspection,a professional third party can deeply analyze the material,internal structure,external structure and safety specifications of products at the beginning of production,find out problems in time and can also evaluate the possible problems in mass production of subsequent products in advance.

Such a service is very valuable to importers from a technical perspective and most importers need to confirm the sample of the order when negotiating a purchase order with the exporter.But without knowing the production process for the manufacturing of the product,it is impossible to put forward professional requirements for the exporter’s product manufacturing from a technical level. Usually, more judgment is made on the appearance and style of the product to determine whether the product is suitable for sale in the target market. Often chasing market hot products, refer to the appearance and style of hot products. There is absolutely no ability to do first article inspection on the product.

What is First Article Inspection Services?

First article inspection refers to FAI,which is to inspect the first finished product or a certain number of products at the begging of the production.Checking whether the raw materials,process,design and labeling of the product meet the requirements of the clients.During the first article inspection process,product defects are allowed in the production process and can be improved in time.

First article inspection includes:

- Check whether the technical documents of the first product are correct, complete, coordinated, and effective,which also can guide production.

- Check whether the product processing technology arrangement is reasonable,feasible,suitable for mass production.

- Check whether the raw materials used meet the specified requirements.

- Whether all the selected equipment and the production environment can meet the production requirements.

- Whether the production operators have the corresponding capabilities.

- Whether the quality of the first product is consistent with its quality record and whether the quality problem is dealt with according to regulations.

- Whether the process requested by the client has been signed and approved.

First article inspection is required in the following situations:

- The first product from new items before the process is finalized.

- Check whether the first part of the trial production is in accordance with the design drawing and process.Determine whether the production process and equipment can ensure that the manufactured product meets the design.

- For the discontinuously produced products,the first product resumes production after one year.

- The first product manufactured after the design drawing is changed.

- The first product manufactured after a major change in process.

- The contract requires designation.

Why Do You Need to Conduct the First Article Inspection?

In the first article inspection,the inspector will check the raw materials of the product,whether the design meets the client’s requirements and whether the appropriate process is used in the production process.When it is found that the production of products does not conform to the requirements of clients,corrective measures can be implemented as soon as possible to avoid misunderstanding of products by factories and resulting in greater losses.Before production,identify the inconsistencies in production and make necessary adjustments.

How Does the Factory Conduct the First Article Inspection?

For factories,the purpose of first article inspection is to ensure the correctness of product manufacturing process,ensure product quality and avoid batch nonconforming products. Products that have not passed the first article inspection are not allowed to be produced in batch.

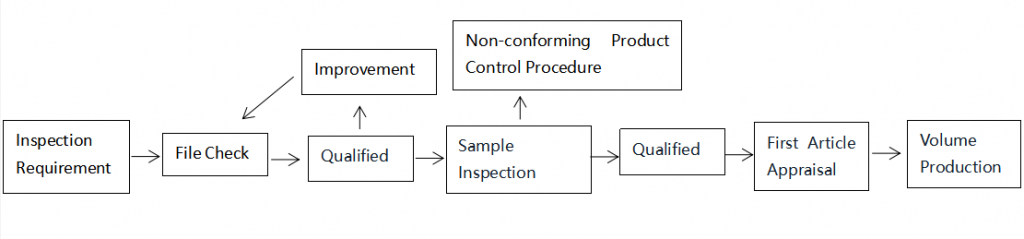

The above picture is a simple process of factory first article inspection.When the products need to be first article inspection,the factory technical department shall prepare the product processing details and relevant requirements according to the products in the order,combined with the product drawings, send them to the relevant operators,organize the production and quality inspection personnel to carry out trial production and assess the first article to determine the final processing technology. In first article inspection services,when the nonconforming products are found,the reasons should be analyzed,solutions should be found and corrective measures should be implemented.The technical department is responsible for organizing the implementation and follow-up verification of the suggestions or improvement measures formed by the first article assessment.

Why do You Need a Third-party Inspection Company to Conduct First Article Inspection?

The main purpose of the first article inspection mentioned above is to find production differences before mass production,implement corrective measures as soon as possible and avoid unnecessary costs. Then,since the factory has already done first article inspection to ensure the production of products,why do you need a third-party inspection company to do first article inspection?

Because factory technicians and inspection departments have been facing the same product for a long time,the same kind of work for a long time leads to weak awareness of product risks.The first article inspection is mainly focus on surface without in-depth analysis of products.The inspectors of the third-party inspection companies are professional technicians,who deeply analyze products and technological processes,and at the same time play a supervisory role on the factory to a certain extent.

Take CQI Inspection Company as an example.When receiving the order from the client for first article inspection,the inspectors of CQI Inspection Company will provide excellent quality by checking the materials and production process of goods. According to samples from the clients,carry out the pre-inspection evaluation and pre-inspection preparation work process,clarify the inspection purpose, requirements,contents and standards,etc. Raise relevant questions and follow up the verification when participating in the first article appraisal.

CQI Inspection Company has a French client who has cooperated for a long time. The main imported products are pulp tableware. CQI Inspection Company found that 100% obvious mold indentation appeared in four corners of pulp tableware before shipment,which affected the appearance of products to a certain extent and even affected the sales of products.However,such problems were discovered only when the products were inspected before shipment and it was too late to rework them.If it is necessary to solve this problem, we can only adjust the mold and reproduce it in batches.Product defects are shown in the following photos:

As a matter of fact, the factory discovered the mold indentation problem when the first product was inspected.However,in the factory’s view,the mold indentation problem is not a product quality problem and even the pulp tableware as a disposable product has low requirements on product quality and does not affect product sales.But in fact,for importers,product appearance is also the main factor affecting product sales.If the French client asked CQI Inspection Company to do the first article inspection at that time,the inspector could find the indentation problem of the product mold on the spot,put forward improvement suggestions and inform the client,improve the product quality and appearance to ensure the product quality and then carry out mass production.Under the supervision of CQI Inspection Company,the factory will not be so “tolerant” of product defects.Instead,they will improve the process of the factory as much as possible and give clients better quality assurance.The appearance of batch will not attract the attention of factories,but such problems can directly affect the sales and even the brand image of clients.CQI Inspection Company’s inspection service is not only a simple inspection,but also hopes to improve clients’ product quality and help clients establish core competitiveness through inspection. CQI Inspection Company’s services aim at thinking from the clients’ point of view and achieve a win-win situation.

Therefore,the first article inspection conducted by a third-party inspection company can avoid misunderstanding of products,ensure that the production of suppliers meets the requirements of clients. Make sure the product quality of clients from the beginning,save the time and money of clients.The factory’s first article inspection only ensures the normal production of products without causing great irreparable losses,while the third-party inspection ensures the quality level of product production,supervises the raw materials of products,avoids the factory cutting corners,reviews the product process,constantly raises questions and improvements to improve the product quality for clients.However,the factory’s first article inspection will not consider the quality problem from the perspective of clients,but will only save its own costs as much as possible. So looking for a third-party inspection company only spends a small amount of money to set a higher standard of product quality,why not?

What is First Article Inspection Process of Third party Inspection Company?

The simple process of the first article inspection of the third-party inspection company is shown in the above picture.Taking CQI Inspection Company as an example,when receiving the client’s first article inspection request,the supplier will be required to provide relevant documents and according to the denouements to make the specific inspection items,special requirements,inspection contents,implementation standards, etc.

During on-site inspection,the inspector shall check whether the process, technical documents and drawings based on which the first article is produced are correct,complete and effective.Check whether the test data of the first article meets the design and product quality requirements of the clients. At the inspection site,the inspector will put forward the first inspection questions and relevant suggestions from the aspects of product raw materials,production process and so on and issue an inspection report according to the quality characteristics of the products inspected on site.The factory can implement corrective measures according to the inspector’s on-site opinions and finally conduct re-inspection to ensure product quality.

What Are the Differences Among FAI(First article inspection), IPI(Initial Production Inspection),DPI(During Production Inspection)and PSI(Pre-shipment inspection)?

Completed quantity of products

Refers to the first product in trial production.In mass production, it generally refers to a certain number of products at the beginning.

10%-20% of the ordered quantity of products.

30%-50% of the ordered quantity of products.

100% of the ordered quantity of products.

Purpose

Check whether the raw materials and process of products meet the requirements of clients.

Check the effectiveness of the products in the production process, find the nonconformities with the first appraisal in time and correct them in time.

Check the production progress of products to reduce the risk of delay in shipment. Supervise the factory production process and ensure the product quality.

Reflect whether the overall product quality meets the client’s expected requirements.

Scope of application

Mainly applicable to industrial products.

All products.

All products.

All products.

Scope of inspection process

Any potential problems in production resources, raw materials,schedule and management.

Potential problems in process,production schedule and etc.

Production status, semi-finished products and finished products are randomly selected.

Randomly select finished products.

Test factors

Raw material quality, process,style design,label, product appearance and product quality test.

Process design, labeling,product appearance and quality testing,etc.

Process design,inspection of semi-finished products and product quality,packaging and packaging methods.

Process design, packaging and packaging methods, product appearance and product quality,and potential risk inspection of product quality.

From the table, we can clearly compare FAI,IPI, DPI and SPI.The significance of each inspection is different. The significance of each inspection is summarized as follows:

Corrective measures can be implemented before mass production of products,so as to avoid misunderstanding of products by factories and resulting in greater losses.Before production,identify the inconsistencies in production and make necessary adjustments.

Checking whether the raw materials meet the requirements is the first step to ensure the product quality,helping the factory to improve the process problems,improve the product quality and avoid losses.

Check the feasibility of mass production after the products are put into production,find problems in time and make improvements to reduce product losses.

It can ensure that the product technological process is well implemented in the whole production process.Make sure that the product quality meets the requirements.Many quality problems can appear during product inspection,which can be corrected in time and reduce the risk of product delivery delay.

In the pre-shipment inspection of products,it plays a supervisory role in the factory quality,finds out the product quality problems and provides relevant suggestions on the inspection site to help the factory continuously improve the product quality.Help clients control the quality of products,enhance the core competitiveness of products and establish their own brands.

What Are the Characteristics of the First Article Inspection Report?

After the first article inspection,a first article inspection report will be issued.Generally,the conclusion of the inspection report of first article inspection includes three parts: pass,conditional pass and fail.When the conclusion of the first article inspection is pass,it means that the process does not need rectification and can be mass-produced.When the conclusion is conditional pass,the small defects can be rectified and mass production can be carried out.If the conclusion is fail,it is necessary to carry out all rectification and do first article inspection again and batch production can only be carried out after passing.

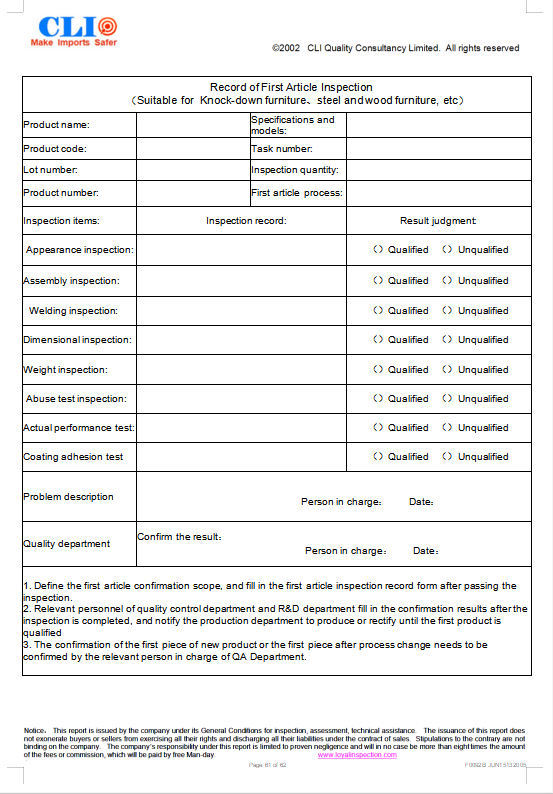

Take CQI Inspection Company as an example please check the first article inspection report of CQI inspection company.

The first article inspection is a very important step before the production of products.Many importers are thousands of miles away from China,they conduct the first article inspection through third-party inspection companies to ensure whether the production of products can meet the requirements.Keep improving and upgrading on the basis of ensuring the quality of products.

CQI Inspection’s Comments and Summary

This article explains the first article inspection in all aspects through seven questions frequently asked by importers.In this paper,the differences of first article inspection services between factories and third-party inspection companies are introduced,so that importers can better understand different first article inspection.At the same time,the inspection services of third-party inspection companies are divided into four aspects: FAI,IPI,DPI and SPI. Many importers don’t understand the differences between these four inspections,so they can’t choose the inspection services.Therefore, this article compares and analyzes these four services through a table.Importers can intuitively see the differences between the four inspection services.When there is a need for inspection services, they can easily find their own inspection services through this table.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.

For Safer Imports

Search

Catalogue

Recent Post

- CQI Inspection Report

- Folding Table: Technological Comparison Between Two Factories

- Tear off the Label Made in China of “Good Quality and Low Price”, Don’t Spoil the International Market

- Do You Know Those Important Material Tests for Car Floor Mats ?

- In 3 Months, Furniture Maker Improves Quality So Much, But Why…

2543 2607 2659 2667 2676 2682 2683 2685 2687 2692 2693 2699 2700 2705 2708 2714 2715 2716 2743 2744 2746 2748 backpack defect check Children furniture quality control China disposable medical gloves Electric toothbrush cost Electric toothbrush inspection Electric toothbrush waterproof inspection Electronic scale quality inspection Glove testing consultation infrared thermometer testing consultation Lighter inspection Lighter process inspection Mask inspection nitrile gloves inspection Pajamas process inspection Plastic clip quality check Quartz watch inspection Quartz watch process inspection Sofa bed inspection solid flooring inspection stainless steel quality control Umbrella process inspection Wenzhou shoes inspection Zhangzhou watch inspection

BLOG

- CQI Inspection Report

- Folding Table: Technological Comparison Between Two Factories

- Tear off the Label Made in China of “Good Quality and Low Price”, Don’t Spoil the International Market

- Do You Know Those Important Material Tests for Car Floor Mats ?

- In 3 Months, Furniture Maker Improves Quality So Much, But Why…