Spell Over What is Commodity Inspection in One Article

By For Safer Imports • 07/02/2021 • No Comments

With the pace of economic globalization, it has become one of the important business strategies for enterprises to reduce costs and improve operating profits through cross-border procurement. Commodity inspection can effectively ensure that the quality of purchased goods meets the requirements, and timely deal with unqualified goods, which is an important link in transnational procurement. In a sense, procurement and supply chain management can make an enterprise the cradle of profits, and also make an enterprise the grave of profits. Christopher, a famous American economist, said: “There is only supply chain in the market, but no enterprise. The real competition is not between enterprises, but between supply chains.” Therefore, controlling the supply chain has become the most important part in today’s economy and trade.

China has become the world’s largest manufacturing country, and the manufacturing industry’s share of the world has risen to 19.8%. It is a producer of export commodities for importers from various countries. The full bloom of China’s manufacturing industry is very rare in human history. The types of industrial manufacturing are the most comprehensive in the world, and each manufacturing industry chain has covered the low-end and is moving towards the high-end. Due to historical reasons, the history of manufacturing in China is about 40 years, and it is still continuously improving. Moreover, in the field of consumer goods manufacturing in China, its export target is global, including both developing countries and developed countries in Europe and America. Taking China’s plastic toys as an example, the Chinese toy industry chain can not only meet the extremely demanding import requirements of European and American toys, but also take into account the cost-effectiveness requirements of the developing countries, even the requirements of low prices.

Such an industrial chain structure is unimaginable for importers. Faced with the temptation of low prices and severe quality risks, how to deal with different types of Chinese manufacturers is a complicated business, and it is also a matter of knowledge. The perfect quality and safety management capabilities of the cross-border procurement supply chain is very important for the company management of importers from all countries! Ensuring the quality and safety of imported goods is the top priority!

As a professional third-party inspection company, CQI will explain in detail what is commodity inspection?

Commodity Inspection refers to the manufacturer, buyer or third party of the commodity under certain conditions, with the help of a certain means and method, according to the contract, standards or relevant laws, regulations and practices outside China, the quality and specifications of the commodity , Weight, quantity, packaging, safety and sanitation, etc., and make a pass or fail acceptance judgment or to protect the legitimate rights and interests of buyers and sellers, to avoid or resolve various risk losses and disputes between the division of responsibility, which is convenient Business activities related to the issuance and settlement of commodities and the issue of various certificates.

Among them, the quality inspection of commodities is the central content of commodity inspection. The narrow sense of commodity inspection refers to the quality inspection of commodities. Therefore, commodity inspection is arranged for better quality control.

What are the specific contents of Commodity Inspection?

- Check whether the goods supplied by the factory meet the quality requirements stipulated by Chinese laws and regulations or relevant Chinese standards;

- To avoid delays in delivery and product defects in a timely manner, take emergency and remedial measures at the first time;

- Reduce or avoid consumer complaints, returns, and loss of business reputation caused by receiving inferior products;

- Reduce the risk of compensation and administrative punishment caused by selling inferior products;

- Verify the quality and quantity of the goods to avoid contract disputes;

- Compare and select the best supplier and obtain relevant information and suggestions;

- Reduce the high management fee and labor cost for monitoring and inspecting products.

The main basis of commodity inspection

It has been introduced above that the content of commodity inspection includes whether the quality, specification, quantity and packaging of goods meet the requirements, so the basis of inspection is mainly based on the commodity standards and the relevant provisions stipulated in the purchase and sale contract;

Commodity standards are generally divided into Chinese domestic standards and International standards.

Chinese standard

Chinese standards are technical requirements that need to be unified throughout China. The standards formulated by the standardization administration department under the State Council are equivalent to the current ISO9000:2000 standards. For example, the Chinese standard of KN95 mask is GB2626-2019.

Chinese standards are technical requirements that need to be unified throughout China. The standards formulated by the standardization administration department under the State Council are equivalent to the current ISO9000:2000 standards. For example, the Chinese standard of KN95 mask is GB2626-2019.

It is mainly produced by formulating enterprise standards as the basis for organizing production when the products produced by enterprises do not have Chinese standards and industry standards. If there are Chinese standards or industry standards, China encourages enterprises to formulate enterprise standards that are stricter than Chinese standards or industry standards. Enterprise standards can only be used within the enterprise.

International and regional standards

International standards refer to the standards formulated by the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and other international organizations.

Regional standards, such as those formulated by the European Union, include ROHS, REACH and so on.

Purchase and sale contract

This document, which is very important in trade, will include the specification, quantity, weight, packaging and the quality requirements. It is also an important basis for commodity inspection, because it will reflect the requirements of buyers for their products.

Method of commodity inspection

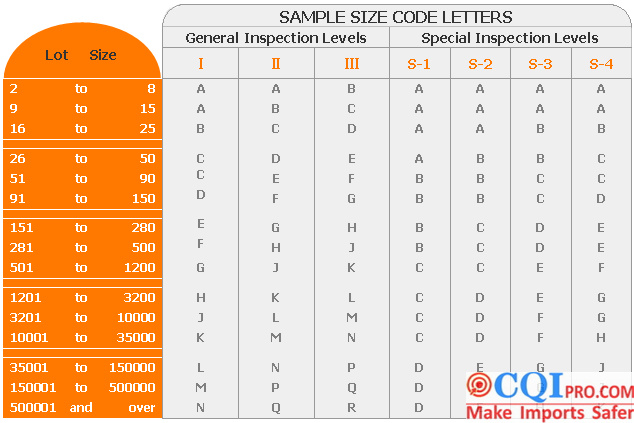

In large-scale orders, sampling inspection is mainly used. A researcher in the United States found that 68% of unqualified products were found in the first time, 18% in the second time, 8% in the third time, 4% in the fourth time and about 2% after four times. In theory, full inspection is better, but it takes a lot of manpower and costs a lot. Therefore, sampling inspection is a common form of commodity inspection at present, and the sampling standard adopted by most third-party inspection companies, including CQI inspection companies, is ANSI/ASQC Z1.4-1993 Single Sampling Plan for Normal Inspection (ISO 2859-1, MIL-STD 105 E, or BS 6001)

There are many methods of commodity quality inspection, which are usually divided into sensory inspection and physical and chemical inspection:

Sensory test method

Sensory inspection refers to the inspection method that uses human sensory organs as inspection instruments to judge or evaluate the sensory quality characteristics of goods such as color, fragrance, taste, hand feeling and timbre under certain conditions.

Sensory test method is fast, economical, simple and easy, does not need special instruments, equipment and places, does not damage commodities, and has lower cost, so it is widely used.

Sensory inspection method generally cannot test the intrinsic quality of goods. The inspection results are often influenced by factors such as the technical level, work experience and objective environment of inspectors, which are subjective and one-sided, and can only express the quality of goods with technical terms or scoring methods, but can not get accurate values.

The types of sensory inspection mainly include food, textiles, clothing, light industrial products, chemical products and so on.

Physical and chemical inspection method

Physical and chemical inspection method is a method to determine and analyze the quality of goods with the help of various instruments and equipment or chemical reagents. Physical and chemical inspection is often carried out in laboratories or special places, so it is also called laboratory inspection method. Physical and chemical tests are mainly used to test the composition, structure, physical properties, chemical properties, safety, hygiene, environmental pollution and destruction, etc.

Physical and chemical inspection method needs certain instruments and equipment and experimental places, and the cost is high; When testing, it is often necessary to destroy a certain number of goods, which is costly; Long inspection time; Need specialized technical personnel to carry out; For some sensory indicators of some commodities, such as color and taste, there is still nothing to do.

Physical and chemical inspection method needs certain instruments and equipment and experimental places, and the cost is high; When testing, it is often necessary to destroy a certain number of goods, which is costly; Long inspection time; Need specialized technical personnel to carry out; For some sensory indicators of some commodities, such as color and taste, there is still nothing to do.

Therefore, the physical and chemical inspection method is seldom used directly in commercial enterprises, and it is often used as a supplementary inspection of sensory inspection, or a special inspection agency is entrusted to conduct physical and chemical inspection.

This is a common method of commodity inspection, through sensory and physical and chemical inspection, before the sale of goods, analyze the quality of goods to avoid after-sales risks. For traders, this is an indispensable step in trade. For example, in 2020, this COVID-19 pneumonia, no one thought that masks had become a hot product. All countries in the world purchase masks in China, but because the quality of masks will be affected by raw materials and production technology, such epidemic prevention products as masks need to pass laboratory tests or related tests of third-party inspection companies, so as to ensure the quality of masks for importers thousands of miles away and achieve the purpose of safe sales.

Many importers will wonder whether all export commodities must be inspected.

I think so, because importers can’t confirm with their own eyes whether the bulk goods meet their own production requirements, and they are worried that the quality problems will not be remedied until they arrive at the destination port, so they are all looking for effective methods to control the quality of Chinese exported products. At present, the quality control of China’s exported products depends on government laws and regulations on the one hand, and commodity inspection on the other hand. Importers can effectively make up for any loopholes in the quality and risk management plan through independent third-party service providers, which enables global importers to have greater flexibility when building their own procurement centers in China and outside China, and can also work together with suppliers to ensure strict quality and risk management processes are implemented.

Moreover, in more and more countries, when importing goods, the customs will require the goods to provide inspection reports or certificates from third-party organizations. COC (certificate of Conformity), for example, is one of the customs clearance certificates in the Middle East or Africa. Most COC certification needs two steps, one is document review, and the other is commodity inspection. Moreover, it is required to conduct pre-shipment inspection and inspection in the export nations.

Since it is an export commodity, most importers will choose commodity inspection service, because it is impossible for them to come to China to review each batch of orders in person, which will cost them a lot of manpower, material resources and time. Therefore, importers will choose the inspection service of third-party inspection companies, which will tailor the inspection service according to the status of commodities in different production periods. Mainly includes the following five inspection services:

The inspectors inspect the raw materials, primary processed products and parts produced by random sampling.

The inspectors inspect the semi-finished products on the production line or the finished products just off the production line, check the defects and deviations, report them to the manufacturer, and propose effective methods to correct the errors and deviations.

Before delivery of finished products, inspection personnel check the quality of bulk goods before delivery (generally, 100% produced and 80% packaged),and check the details of goods such as quantity, process, function, color, size, specification and packaging. Sampling method is in accordance with internationally recognized standards such as iso2859/nfx06-022/ansi/asqcz1.4/bs6001/din40080. At the same time comply with buyers AQL sampling level.

After the sampling inspection before the final product is shipped, the inspectors will assist the manufacturer to confirm the packing used, whether it meets the due cleaning condition and packing conditions, etc. in the factory base, warehouse or packing transmission process.

According to the requirements of customers, the inspection company assigns factory auditors to inspect the working conditions, production conditions, facilities, manufacturing equipment, manufacturing methods, quality assurance management and personnel of production enterprises, and puts forward corresponding explanations and opinions, which can not only investigate the problems that may cause quality accidents for customers, but also provide rectification opinions.

How should importers arrange commodity inspection for their orders?

With the development of China’s foreign trade, China has become a big manufacturing country in the world, and more and more importers purchase various commodities in China, so the demand for pre-shipment inspection is also growing rapidly, and there are many third-party inspection companies in China. Corresponding to importers of different sizes, the services provided by third-party inspection companies of different sizes and histories are also different. Importers should choose corresponding third-party inspection companies according to their own needs. After choosing a suitable third-party inspection company, you can arrange commodity inspection according to the following steps:

Send the order documents and inspection requirements, and the third-party inspection company will sort out the basic data.

Confirm the inspection time before shipment, and know the scale of the factory and the testing equipment that can be provided, so that the inspector can prepare the necessary measuring tools in advance and evaluate the potential risks of the factory.

CQI third-party inspection company will provide corresponding check list for the buyer’s reference, confirm the actual inspection requirements with the clients.

According to the analysis results of QA department, the inspection documents are sorted out for the second time, which is helpful for inspectors to fully make control of the inspection risks in factory during inspection.

The office account manager will keep in touch with the factory and the inspector to avoid the blind spot of the inspector. If there are special circumstances, it will be resolved in time and fed back to the customer.

The inspector shall provide the actual findings on site according to the inspection requirements, and the client shall determine whether to arrange shipment.

To learn about Commodity Inspection Report, you can click this.

Finally, for clients who often import from China, CQI will also provide a report quarterly or semi-annually, which can record the conclusion of each factory’s shipment and inspection in detail, and buyers can use it to analyze which factories’ quality control is in place. Through this series of inspections, reports and statistical analysis, importers can have a long-term tracking of their own procurement chain and systematically feedback the necessity of supply chain management; For the factory, because the buyer has to pay special attention to the order because of commodity inspection for each ticket, he certainly tries his best to improve the quality of his products and reduce the complaints caused by quality problems.

Now, CQI explains why commodity inspection can help importers reduce risks with the actual cases of third-party inspection companies.

This is a batch of export desks, with a total quantity of 3,200 sets.The buyer has arranged three inspections, the first is the mid-term inspection During inspection, the second is the final inspection PSI inspection, and the last is the loading inspection.

During the mid-term inspection, the inspector found rust on the bottom of the chair. At that time, more than 100 sets of this model had just been produced. After inspector discovered this problem, the supplier immediately arranged for the factory to re-produce. Re-pickling the metal parts and spraying them after pickling. Identify problems in advance through commodity inspection, so that the factory can rectify them immediately. When the inspector went to the factory for PSI for the second time, this problem had been well controlled. For the factory, it is much easier to rework 100 sets of problems found than the last 3200 sets of problems found, and there is no need to worry that rework will delay the delivery time for too long. Therefore, qualified suppliers always want third-party inspection companies to help them control the product quality. Moreover, the inspection fee is paid by the client, so why not the supplier?

All the problems mentioned above are product quality. Now, let’s briefly talk about product packaging and quantity.

Many customers will ask the third party to arrange inspection when bulk goods being loaded in containers in the factory. One purpose is to ensure the safe use of containers and avoid and prevent the occurrence of cargo damage caused by container problems. Another purpose is to ensure that the quantity of products put in container is consistent with the requirements of the list.

The container is provided by the wharf, and the truck driver is responsible for pulling the container to the factory. In the following figure, the inspector found the small hole in the cabinet after checking the light leakage on the spot, and asked the factory to arrange for the container to be replaced, or immediately carry out welding repair.

Through these two examples, we can know that the third-party service organizations responsible for quality management play an effective role in compensating quality and managing potential risks in trade.

CQI Inspection’s Comments and Summary

Commodity inspection refers to the comprehensive evaluation of commodity quality advantages by using scientific inspection techniques and methods according to various quality indexes specified in commodity standards.The task of commodity inspection is to analyze and research from the purpose and conditions of use of goods, investigate the composition, structure and nature of goods and their influence on the quality of goods, and determine the use value of goods; promote the improvement of commodity quality, and provide basis for selecting suitable packaging, storage and transportation methods. Moreover, arranging commodity inspection can also properly avoid or solve various risks, losses and disputes on division of responsibilities, which is convenient for commodity handover and settlement. Therefore, commodity inspection is an important link to enable international trade activities to proceed smoothly, that is,commodity inspection is an indispensable link in the process of import and export goods handover.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.

For Safer Imports

Search

Catalogue

Recent Post

- CQI Inspection Report

- Folding Table: Technological Comparison Between Two Factories

- Tear off the Label Made in China of “Good Quality and Low Price”, Don’t Spoil the International Market

- Do You Know Those Important Material Tests for Car Floor Mats ?

- In 3 Months, Furniture Maker Improves Quality So Much, But Why…

2543 2607 2659 2667 2676 2682 2683 2685 2687 2692 2693 2699 2700 2705 2708 2714 2715 2716 2743 2744 2746 2748 backpack defect check Children furniture quality control China disposable medical gloves Electric toothbrush cost Electric toothbrush inspection Electric toothbrush waterproof inspection Electronic scale quality inspection Glove testing consultation infrared thermometer testing consultation Lighter inspection Lighter process inspection Mask inspection nitrile gloves inspection Pajamas process inspection Plastic clip quality check Quartz watch inspection Quartz watch process inspection Sofa bed inspection solid flooring inspection stainless steel quality control Umbrella process inspection Wenzhou shoes inspection Zhangzhou watch inspection

BLOG

- CQI Inspection Report

- Folding Table: Technological Comparison Between Two Factories

- Tear off the Label Made in China of “Good Quality and Low Price”, Don’t Spoil the International Market

- Do You Know Those Important Material Tests for Car Floor Mats ?

- In 3 Months, Furniture Maker Improves Quality So Much, But Why…